Delivery of new tile machinery

Salmon Trade provides complete equipment that follow all the productive line: from the preparation of the raw materials to the final line, with the opportunity to incorporate “second-hand and regenerate” machines, accessories and equipment of new production.

Thanks to our experience in this sector, to the reliability and to the advisory service and high qualified assistance we are the ideal partner for the delivery of ceramic rollers, piston pumps for ceramics slips, conveyor belt, diamond tools etc. for the ceramic industry.

For further information about the delivery of ceramic rollers or if you want to know the costs of our machines, do not hesitate to contact us, by phone or filling out the form that you can find in the area Contacts.

Located in Casinalbo di Formigine, our services are available all around the world.

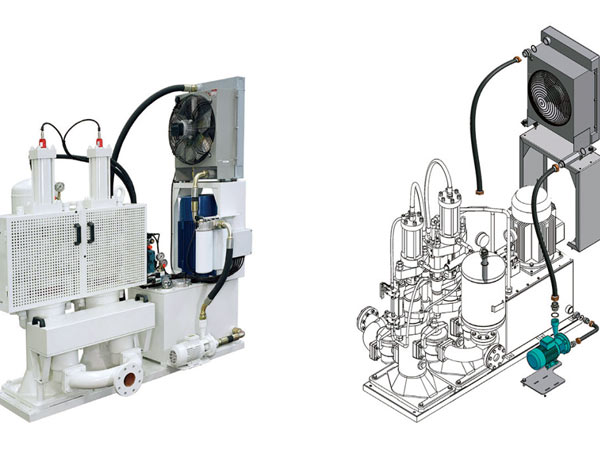

Piston pumps for slip

According to the extent, to the technical characteristics and the equipment, piston pumps are available in different versions. They are used for the transport of ceramic slips and dense and abrasive suspensions and they are also suitable for the power supply of atomizers and filter presses.

Machines for roller cleaning

Machines for cleaning and correction of rollers by a special diamond tool controlled by an automatic system. Centring and placement of the milling cutter on the roller through photocells.

Propellers for powder transport

The technology developed by Air-Tec system for pneumatic conveying in dense phase allows the handling of loose materials in powder or granules inside a pipeline for distances over 500 m and capacities greater than 100 tons / h.

Dense phase pneumatic conveying stands out for low transport speed and a high ratio of product/air efficiency. The indicative ratio between air (or other gaseous fluids) and product is as follows:

Dense phase about 30 l of transport gas per 1 kg of product.

Other systems about 1000 l of transport gas per 1 kg of product.

Dense phase transport preserves the integrity of the material, also in case of mixtures of several products. Low speed is indicated for very fragile products, such as atomized ceramic, coffee, rice, fiberglass. Using dense phase pneumatic conveying tube wear is significantly lower than other systems.

Moreover, the low quantity of gas used does not disperse the volatile substances and preserves any aroma and the use of inert gases prevents the oxidation of the products.

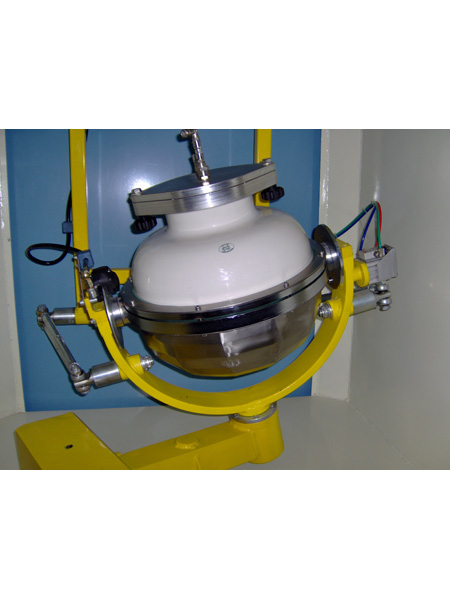

Mill DS-10

The mill DS-10 is a lab machine that permits the preparation of digital decoration inks and screen printing pastes in very short times.

Indeed, most of the glazing for production can be minced in 60 minutes maximum with residual base about 3-5% using a sieve by 16000 mesh (3-5 gr. on a base of 100 gr. of product). The inks printing pastesrequire 120-150 minutes max with a residual base of 0,2-0,3 % using always a sieve by 16000 mesh (0,2-0,3% on a base of 100 gr. of product).

Contact us for a free-of-charge consultancy.

Located in Casinalbo di Formigine, our services are available all around the world.